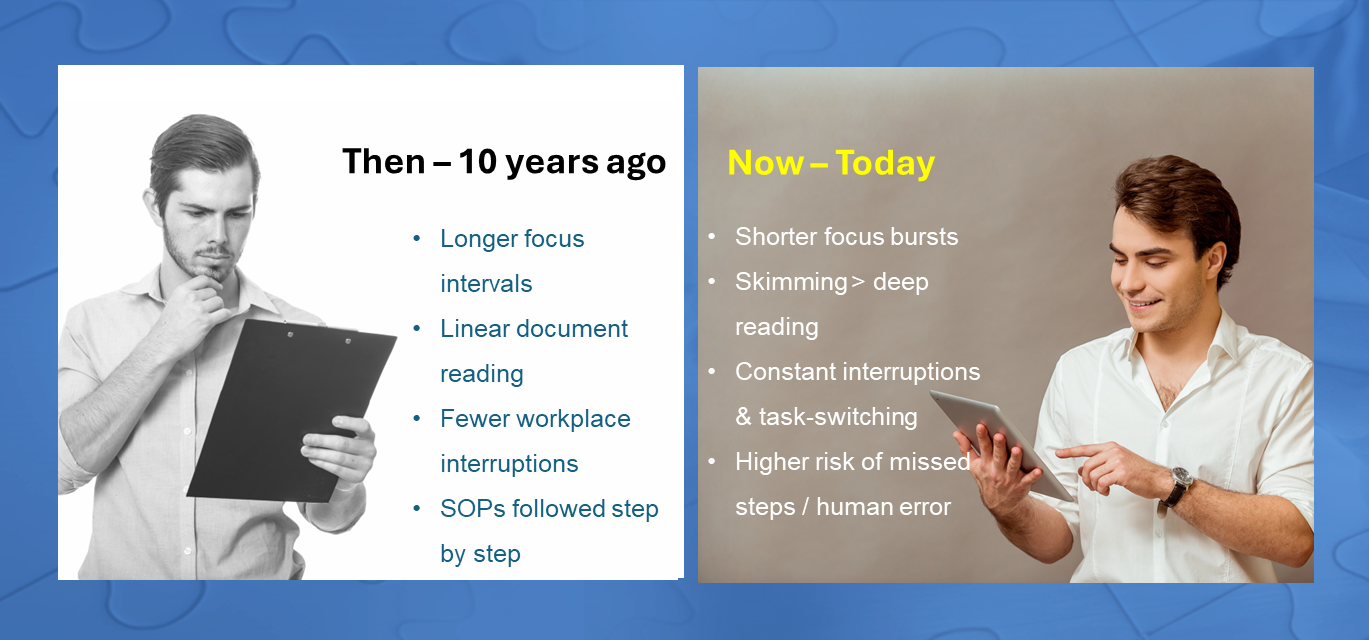

In the last decade, the way people process information has shifted dramatically. Reports, procedures, and work instructions that once held steady attention are now competing with fragmented work patterns, constant interruptions, and the pervasive influence of social media. While catchy headlines often claim that “humans now have an eight-second attention span,” the real story is more nuanced — and more concerning for those of us in life sciences and other regulated industries.

Recent scientific research shows that attention is not vanishing, but it is changing. Frequent exposure to rapid, short-form content (think scrolling through TikTok or Instagram reels) trains the brain to expect novelty and brevity. At work, this translates into shorter focus intervals, more task switching, and reduced ability to stay with long, complex documents. Gloria Mark, a professor of informatics at UC Irvine, has shown that workers today switch tasks nearly every three minutes on average, with resumption often taking much longer than expected. These patterns don’t mean people can’t focus; they mean it’s harder to sustain deep attention without intentional design and support.

For quality leaders, this shift is more than a cognitive curiosity — it’s a risk driver for human error.

Attention Lapses and Human Error in Regulated Work

Studies in occupational psychology and human factors highlight that attention failures are a leading cause of workplace errors and near misses. Brian A. Anderson and colleagues (2023) demonstrated that when workers become desensitized to repetitive hazards or distracted from procedures, they are significantly more likely to overlook critical cues. In life sciences manufacturing, that could mean missing a sterilization step, misinterpreting a change order, or failing to notice an equipment alarm.

Here are some of the mechanisms researchers have identified:

- Reduced sustained attention: Employees skim long SOPs or technical documents, increasing the chance of missing critical instructions.

- Task switching and interruptions: Each disruption adds “resumption lag,” leading to skipped steps or forgotten requirements.

- Habituation: Repeated exposure to similar warnings or instructions dulls awareness, making important cues easier to ignore.

- Shallower encoding: Rapid scanning reduces long-term retention of procedures and training content.

The implication is clear: as attention patterns change, the risk of procedural deviations and compliance issues grows. In highly regulated industries, where a single overlooked step can escalate into product recalls, regulatory findings, or patient safety risks, this is not an academic concern — it’s a business-critical issue.

What Quality Leaders Can Do

The good news is that QMS design, document strategy, and training practices can be adapted to these new realities. Instead of assuming employees will adapt to long, complex documentation, we can design information and processes that respect human attention limits while reinforcing compliance.

- Redesign SOPs for clarity and action

- Break procedures into short, titled steps (1–3 sentences each).

- Place a one-line “Required Action” or checklist at the top of critical SOPs.

- Highlight safety or compliance-critical steps with icons or callouts.

- Use training methods that go beyond passive reading

- Replace long text-heavy sessions with shorter modules that include scenarios and simulations.

- Integrate spaced repetition so that knowledge is reinforced over time.

- Use readbacks or quick quizzes to ensure retention and comprehension.

- Protect focus during critical work

- Establish “no interruption” zones or time blocks for procedures that demand sustained attention.

- Encourage teams to batch communication rather than disrupt each other in real time.

- Apply human factors design to work environments — clearer labeling, color coding, and standardized formats reduce reliance on memory.

- Support hazard recognition

- Rotate or vary visual warnings to prevent habituation.

- Use active engagement methods (e.g., asking employees to identify risks during training) to strengthen vigilance.

These strategies are not just theoretical. Aviation, nuclear energy, and healthcare have long applied checklists, structured documents, and human factors engineering to counteract attention lapses. In life sciences, adopting these proven practices within your QMS is a practical way to lower error rates while strengthening regulatory compliance.

The Bigger Picture: Attention as a Quality Risk Factor

The regulatory landscape is evolving toward greater scrutiny of human factors and documentation practices. Audit observations related to documentation and purchasing controls consistently rank among the top findings across the industry. As attention spans shorten and work becomes more fragmented, regulators are unlikely to accept “human error” as a root cause without evidence that systems were designed to support human performance.

For quality leaders, the challenge — and opportunity — is to anticipate this shift. By acknowledging the changing cognitive environment, companies can proactively strengthen their QMS to reduce errors, improve training outcomes, and safeguard compliance.

At Q6 Consulting, we believe that quality systems must be designed not only for compliance but also for human performance. As research shows, attention patterns are changing, and ignoring that reality exposes organizations to unnecessary risk.

If your SOPs, training programs, or quality documentation were designed for a different era of workplace attention, now is the time to reassess.

- Are your critical instructions easy to follow at a glance?

- Does your training approach reinforce retention, not just completion?

- Have you built human factors into your QMS to minimize attention-driven errors?

The future of quality leadership is not about blaming individuals for lapses — it’s about designing systems that make the right actions the easiest actions.

Let’s build quality systems that recognize the realities of human attention today and prevent errors tomorrow.

✅ Next Step: Connect with Q6 Consulting to explore how we can help redesign your SOPs, training, and QMS practices to align with the latest human factors research — reducing error risk and strengthening compliance.